Marine Propeller

Libraries:

Simscape /

Driveline /

Engines & Motors

Description

The Marine Propeller block represents a propeller that converts a rotational mechanical motion into thrust for marine applications. You can configure the propeller with fixed or controllable blades. You can parameterize the propeller by using constants, polynomials, or tabulated data to characterize the thrust and torque coefficients. You can provide tabulated advance velocity data, or you can provide tabulated advance angle data to parameterize all four operational quadrants. Propellers that allow negative pitch or that can operate in reverse may include thrust and torque coefficient curves specific to the astern direction, which you can also specify in the block.

You can also include the wake effects of the vessel hull in the block. When you specify a constant wake fraction or enable a physical signal port, and the block calculates the wake effects automatically.

You can use a physical signal to control the blade pitch.

This terminology is helpful for understanding the block:

Wake fraction is the difference between the vessel velocity and the advance velocity expressed as a ratio of the vessel velocity.

Advance velocity is the speed of the flow through the propeller, Va.

Advance ratio is the speed of the flow through the propeller with respect to the propeller tip angular speed expressed as a ratio. The block uses this to determine kT and kQ when you set Parameterization to

Polynomial fitorTabulated data for advance ratio.Advance angle is the angular location of the propeller operational conditions on a four quadrant plot. The block uses this to determine CT and CQ when you set Parameterization to

Tabulated data for advance ratio.Quadrant is the relative two-dimensional location of the propeller operating condition where the vertical axis is Va and the horizontal axis is ω.

Pitch is the ideal translational propeller advance distance for a single revolution.

Open water is when the effects of the hull are not present.

The block equations refer to these quantities:

T is the propeller thrust.

Q is the propeller torque.

ρ is the fluid density. You can specify the fluid density using the Density parameter or the Rho port.

P is the pitch.

D is the Propeller diameter parameter, where one represents

ω is the propeller angular speed input at port R. For more information about using angular units in Simscape™, see Angular Units.

n is the propeller angular speed in revolutions per second, which consistently nondimensionalizes the torque and thrust. The block defines ω = 2πn.

nThr is the Rotational speed threshold parameter.

ε is the Propeller direction parameter.

kT is the thrust coefficient with respect to the propeller rotational speed.

kQ is the resistive torque coefficient with respect to the propeller rotational speed.

pkT is the polynomial thrust coefficient vector or 2-D matrix.

pkQ is the polynomial resistive torque coefficient vector or 2-D matrix.

CT is the thrust coefficient with respect to the relative advance velocity.

CQ is the torque coefficient with respect to the relative advance velocity.

kThr is the Saturation threshold for nondimensional coefficients parameter.

J is the advance ratio.

Va is the advance velocity. Specify the advance velocity using the Va port.

VR is the relative advance velocity at a blade section at 70% of the blade radius.

η is the efficiency.

CT* is the thrust coefficient based on the blade relative advance velocity at 70% blade radius.

CT,TLU* is the reference thrust coefficient vector or 2-D matrix.

C*Q is the torque coefficient based on the blade relative advance velocity at 70% blade radius.

C*Q,TLU is the reference torque coefficient vector or 2-D matrix.

β is the advance angle.

βTLU is the reference advance angle.

Parameterizations

The propeller performance depends on the thrust and resistive torque coefficients. The Parameterization parameter gives you different options to control these coefficients. The propeller output depends on the quadrant where the propeller operates. The block defines the four quadrants as:

First quadrant: +Va, +n

Second quadrant: +Va, -n

Third quadrant: -Va, -n

Fourth quadrant: -Va, +n

The figure shows a visual representation of the quadrants.

When you set Parameterization to

Constant coefficients, you specify the thrust and

resistive torque coefficients directly. Otherwise, the block computes these

coefficients depending on the Parameterization

setting.

When you set Parameterization to Polynomial

fit or Tabulated data for advance

ratio, the block uses the advance ratio, J.

The block uses a numerically smoothed version of the fundamental thrust and

torque equations such that

The block defines the advance ratio as

where the angular speed threshold nThr linearizes the propeller rotational speed, n, for smoothing.

When you set Parameterization to:

Polynomial fit— kT and kQ vary with time according to the values you specify for the polynomial coefficient parameters. The block saturates J to be between 0 and the first positive root of the polynomial and restricts kT and kQ to always be positive. The block calculates the thrust and torque coefficients aswhere pkT and pkQ represent the polynomial coefficients.

Tabulated data for advance ratio— You specify tabulated values for kT and kQ for given values of J or J and P/D, depending on the Blade pitch type parameter.

This basis of the propeller efficiency is the fundamental relationship

When Efficiency sensor is on, and you set

Parameterization to

Constant, the block calculates the smoothed

efficiency as

When Efficiency sensor is on, and you

set Parameterization to Polynomial

fit or Tabulated data for advance

velocity, the block calculates the smoothed efficiency as

When you set Parameterization to Tabulated

data for advance angle, the block uses thrust and torque

coefficients with respect to relative advance angle. The block defines the

advance angle as

where β is cyclic. You must ensure that the coefficient extrapolation and cycle wrapping occur as expected. The block defines the thrust and torque coefficients for relative advance velocity as

where VR is the relative advance velocity at a blade section at 70% of the blade radius, such that

Rearranging the coefficient equations yields the block equations for thrust and torque with respect to relative advance velocity:

When you set Blade pitch to:

Constant, the block calculates the thrust and torque coefficients asControlled, the block calculates the thrust and torque coefficients as

The basis of the propeller efficiency is the fundamental relationship

When Efficiency sensor is on, the block calculates the smoothed efficiency as

When you set Translational connections to

Conserving, the block uses a constant wake

fraction to relate the vessel velocity to the advance velocity. You input the

thrust and velocity of the vessel by using the R2 and

C2 ports. The block computes the advance velocity

as:

where:

V is the vessel velocity. You can specify the vessel velocity relative to the reference by using the R2 and C2 ports, where V = VR2-VC2.

w is the Wake fraction parameter.

When you set Translational connections to

Physical connections, you can use the

Va port to supply the advance velocity as a physical

signal. The block outputs the propeller thrust as a physical signal from the

Th port.

When you set Blade pitch type to

Controlled, you can parameterize the propeller

over a range of pitch-diameter ratios, P/D. You must specify

the P/D range as a vector in the Pitch-diameter

ratio vector, P/D parameter, where each element corresponds to a

row in the kT and

kQ matrices.

Inertia

You can optionally include translational and rotational propeller inertia. To

simulate inertia, set Rotational connections or

Translational connections to

Conserving, and select Model

inertia. When you select Model inertia and set

Rotational connections to

Conserving, set the initial rotational velocity or

torque on the shaft in the Initial Targets section, or set an

algebraically linked variable to high priority to initialize the rotational inertia.

When you select Model inertia and set Translational

connections to Conserving, set the initial

translational velocity or thrust in the Initial Targets

section, or set an algebraically linked variable to high priority to initialize the

translational mass.

Note

For rotational conserving connections, the block logs

Q, the aerodynamic torque, and

Inertia.t.

For translational conserving connections, the block logs

thrust, the aerodynamic thrust, and

mass.f.

You can use an Ideal Torque Sensor or Ideal Force Sensor blocks to log the sum of the inertia and the aerodynamic torque or force, respectively.

Assumptions and Limitations

The block treats the fluid velocity and propeller rotational velocity as quasi-steady in time. Fluid flows uniformly over the propeller.

When you set Parameterization to

Polynomial fit, the block assumes that the propeller torque and thrust coefficients are symmetric with the first quadrant.When you set Parameterization to

Tabulated data for advance ratio, the block assumes the torque and thrust coefficients are identical in the first and third quadrants and the second and fourth quadrants.When you set Parameterization to

Tabulated data for advance angle, the block removes the sign from Va. To attain negative thrusts and torques, you must include the signs in the values of CT and CQ.

Variables

To set the priority and initial target values for the block variables prior to simulation, use the Initial Targets section in the block dialog box or Property Inspector. For more information, see Set Priority and Initial Target for Block Variables.

Nominal values provide a way to specify the expected magnitude of a variable in a model. Using system scaling based on nominal values increases the simulation robustness. Nominal values can come from different sources, one of which is the Nominal Values section in the block dialog box or Property Inspector. For more information, see Modify Nominal Values for a Block Variable.

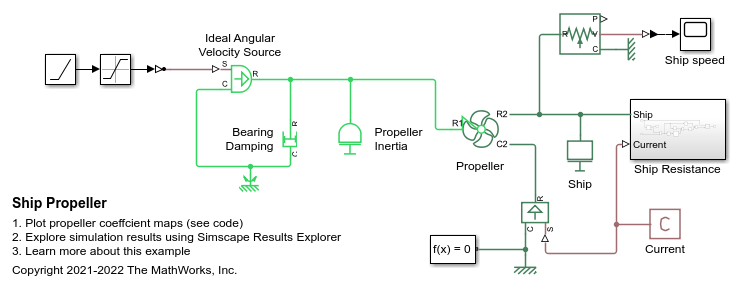

Examples

Ports

Inputs

Outputs

Conserving

Parameters

References

[1] Bernitsas, Michael M., D. Ray, P. Kinley. "Kt, Kq and Efficiency Curves for the Wageningen B-Series Propellers." Report 237. Department of Naval Architecture and Marine Engineering. College of Engineering. University of Michigan, 1981.

[2] Carlton, J. S. Marine Propellers and Propulsion. Second edition. Oxford: Elsevier, 2007.