Automotive DevOps for Model-Based Design with AWS, NXP, and MathWorks

Curt Hillier, NXP Semiconductor

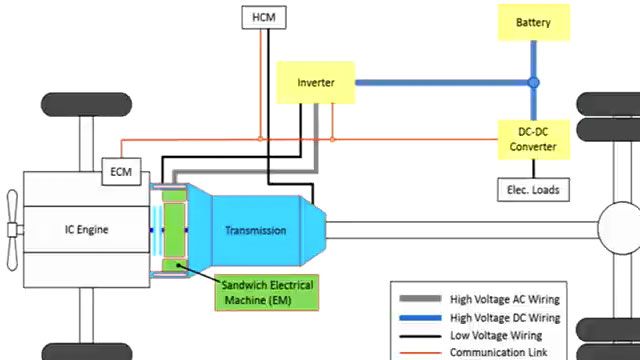

Vehicle features and capabilities are transitioning from being mostly mechanically defined to being software defined. OEMs are adopting agile software development methods to update and maintain this software, driving the need for DevOps. NXP Semiconductors, MathWorks, and AWS have collaborated on a DevOps solution for Model-Based Design utilizing advanced vehicle control algorithms. In this talk, NXP will present the full cloud-to-vehicle solution built with AMS CodeSuite services by using MathWorks design tools targeting NXP automotive processors. This presentation also covers NXP® Model-Based Design Toolbox supporting code execution and profiling on the NXP S32S GreenBox II and NXP S32G GoldBox.

Published: 30 May 2022