Position Control of a PMSM with Simulink and Microchip 32-bit MCUs

Overview

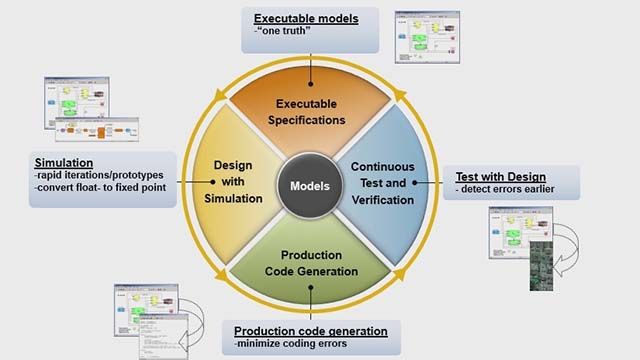

Field-oriented control (FOC) is a common technique for precise position control of permanent magnetic synchronous motors (PMSM). This webinar shows how to use Simulink to implement FOC algorithms for positioning a PMSM and deploy them on Microchip’s ATSAME70, 32-bit microcontroller (MCU). Starting with an FOC algorithm from Motor Control Blockset, we will use Embedded Coder to generate optimized C-code for a Microchip microcontroller. The code generation workflow will feature the use of the MPLAB Device Blocks for Simulink, which provides an integrated development environment and toolchain for configuring and generating all the necessary software to execute complex applications on Microchip MCUs.

Highlights

- Simulating an FOC based position control algorithm in Simulink and Motor Control Blockset

- Generating optimized, production-ready C-code with Embedded Coder

- Deploying code to Microchip PIC32, and SAM controllers using MPLAB Device Blocks for Simulink

About the Presenters

Swathy Pillai: MathWorks

Swathy Pillai is a Product Manager at MathWorks focusing on Motor Control. She holds a master’s degree in Electrical Engineering with specialization in Power Electronics & Drives. Before MathWorks, she worked with L&T Electrical & Automation, Schneider Electric India in R&D division where she was involved in control algorithm development and coding for Low and Medium Voltage industrial drives and other power electronic converters.

Brett Novak: Microchip

Brett is the Motor Control Marketing Manager for Microchip’s MCU32 Division, including responsibility for PIC32 and acquired SAM ARM based devices. He has over 20 years of experience working in the semiconductor industry focused on control theory-based applications including motor and power control.

Purushothamreddy Madduru: Microchip

Purushothamreddy is the principal applications engineer for Microchip’s MCU32 division, specializing in Machine Drives & Power Electronics, and has 9 years of industry experience in Embedded software development for Motor Control applications. He is responsible for MCU32 MPLAB Simulink Device Blocks development and motor control algorithms development for PMSM, BLDC and induction motor drives suitable for industrial and traction control applications. He has a vast knowledge of model-based design including simulation, hardware-in-the-loop, and code generation.

Recorded: 13 Jul 2023